Is the tuning fork level switch really so magical? This article will help you understand its working principle and application scenarios (Part 2)

2025-10-13 15:31

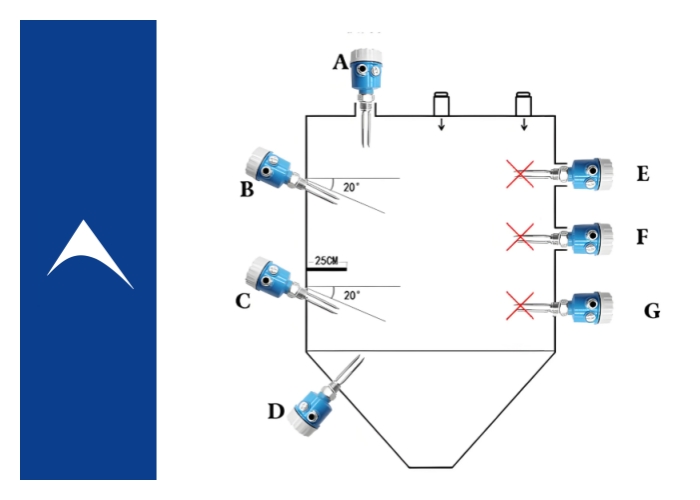

The installation quality of the tuning fork level switch directly affects the subsequent operation stability. The following key points need to be strictly controlled:

Installation Direction

The plane of the fork body must be consistent with the direction of the medium flow to avoid measurement errors. The direction can be judged by the marking points on the process connection. For example, it is correct when the marking point is facing up or down, and incorrect when it is facing left or right. When installing on the side, ensure that the two fork bodies are on the same horizontal plane.

Installation location

The installation location should avoid the material inlet to prevent direct impact. When installing in an overpressure or underpressure container, confirm that the sealing material meets the temperature and pressure requirements. When installing outdoors or in a humid environment, the cable should be laid with the bend facing down to prevent moisture, and the direction of the instrument head can be adjusted so that the cable port is facing down to enhance protection.

Model Matching and Installation Method

Before installation, confirm that the instrument model matches the on-site working conditions (pressure, temperature, and medium characteristics). Conventional installation methods include vertical, horizontal, or inclined downward installation. For highly adhesive materials, it is advisable to install vertically downward. For materials containing blocky particles, it is advisable to install vertically or inclined, and upward installation is strictly prohibited. Before installation, it is recommended to calibrate the sensitivity with a small amount of medium samples, and select top, side wall, or pipeline installation according to the actual monitoring requirements (high level, low level, or pipeline empty flow monitoring).

Connection Method

The process connection needs to select flange, thread, or clamp method according to the on-site conditions. The cable connection must be operated strictly according to the wire system and power supply requirements specified in the product manual. After connection, be sure to tighten the cover and the wire inlet. When applied in an explosion-proof area, the corresponding safety specification manuals and regulations must be fully complied with.

Matching of material properties

Special attention should also be paid to the matching of material characteristics. For viscous materials, it may be necessary to select a tuning fork with a special design to prevent material adhesion from affecting the detection accuracy.

The tuning fork level switch, with its excellent performance, has been widely applied in many industries and has become a key equipment in the industrial production process, providing strong support for the efficient and stable operation of various industries.

(1) Chemical Industry

In the chemical industry, this equipment is mainly used for powder metering and storage. For example, it can monitor the level of plastic granule silos, providing real-time feedback data to ensure the smooth progress of the process. At the same time, its 316L stainless steel tuning fork has excellent corrosion resistance and is suitable for corrosive liquid storage tanks such as hydrochloric acid and sulfuric acid, ensuring accurate liquid level detection and production safety.

(2) Food Industry

In the food industry, this equipment can real-time monitor the level of materials such as grains and feeds, and send a signal when the threshold is reached to avoid material overflow or shortage. For low-density materials such as flour, it can achieve precise detection with a high sensitivity of 0.008 g/cm³, and at the same time meet the hygiene standards to ensure food safety.

(3) Building Materials Industry

In the entire process from raw material storage to finished product packaging in cement production, this equipment can stably detect the level in a high-dust environment with strong anti-interference ability. It can control the level in the packaging line hopper to ensure packaging quality and efficiency. At the same time, it is suitable for precise monitoring of building material raw materials such as lime and gypsum, helping to improve production efficiency.

(4) Metallurgical Industry

Facing the high-temperature and high-corrosion environment of the metallurgical industry, this equipment, with its high-temperature resistance characteristics, can reliably detect the level of powder smelting silos and granular hoppers, ensuring material supply and smooth process flow, and adapting to complex production requirements.

(5) Environmental Protection Industry

In the field of environmental protection, this equipment is used for level control in the process of solid waste treatment to optimize the treatment process and improve efficiency. At the same time, it can real-time monitor the dust level in the dust control system, issue timely warnings, prevent dust pollution, and support environmental protection work.

tuning fork level switch tuning fork level switch tuning fork level switch tuning fork level switch tuning fork level switch