Is the tuning fork level switch really so magical? This article will help you understand its working principle and application scenarios (Part 1)

2025-10-11 14:21

In the complex processes of industrial production, accurately grasping the material level is of crucial significance. It not only directly affects production efficiency but is also closely related to product quality control, cost optimization, and production safety assurance. As a highly efficient and reliable level detection device, the tuning fork level switch has gradually become an indispensable key component in the field of industrial automation and plays an increasingly important role in the level detection process.

The tuning fork level switch can achieve key detection functions in industrial production scenarios, and its unique working principle is the core support. This device completes level detection based on the principle of mechanical vibration. Through the coordinated operation of various key components, it realizes the full-process closed loop from signal drive to detection output.

Key Components

The core components of the tuning fork level switch include the tuning fork body and the piezoelectric crystal installed on the tuning fork base. Among them, the piezoelectric crystal has the dual functions of a "driving source" and a "sensing element". On the one hand, as a driving element, when an external electrical signal is applied to the piezoelectric crystal, the crystal will produce regular mechanical deformations, which in turn drive the tuning fork closely connected to it to generate mechanical vibrations at a specific frequency. The normal vibration frequency range of the tuning fork is 100Hz - 150Hz, and different models vary according to design requirements. On the other hand, as a sensing element, the piezoelectric crystal can capture the changes in the vibration state of the tuning fork in real time. The tuning fork body, as the component that directly contacts the material, the change in its vibration state is the core basis for judging the presence of the material.

Working Process

After the device starts, the piezoelectric crystal first drives the tuning fork to vibrate stably and freely at its resonant frequency, and the amplitude is the largest at this time. When the tuning fork comes into contact with the material, the material will dampen the vibration, resulting in a significant attenuation of the amplitude. This change is captured by the piezoelectric crystal in real time and converted into an electrical signal. The internal intelligent circuit then processes and analyzes this signal, and accurately identifies the presence of the material by judging whether the amplitude is lower than the preset threshold. Finally, the device will output a switching signal (such as a relay signal) to drive an alarm or control device, achieving automatic level detection and control.

The tuning fork level switch has significant competitiveness in the field of industrial level detection due to its excellent performance advantages, providing a reliable solution for material management under complex working conditions.

High Sensitivity

This device has extremely high sensitivity for material detection and can achieve precise detection of extremely low-density materials. By optimizing the volume of the tuning fork and the piezoelectric drive structure, some advanced models of tuning fork level switches can detect materials with a minimum density of 0.008g/cm³. Even for extremely light powder or granular materials, they can still accurately trigger the switch action and achieve precise judgment of the material's presence state. This characteristic greatly broadens the application range of the device and can meet the detection requirements of special materials in industries such as the food industry (such as light flour, milk powder) and the chemical industry (such as low-density powder raw materials).

Strong Anti-interference Ability

There are often complex environmental factors such as high dust, strong vibration, and strong electromagnetic interference in industrial production sites. However, the tuning fork level switch has excellent anti-interference ability. Its detection method of converting mechanical vibration signals into electrical signals can effectively avoid the influence of the vibration environment and is not affected by interference sources such as high dust and strong electromagnetic fields. Even in harsh environments such as high-dust silos in cement plants and areas around strongly vibrating conveyor belts in mines, it can still operate stably and reliably, ensuring the accuracy and safety of level control and providing solid support for the stability of the production process.

Robust and Durable

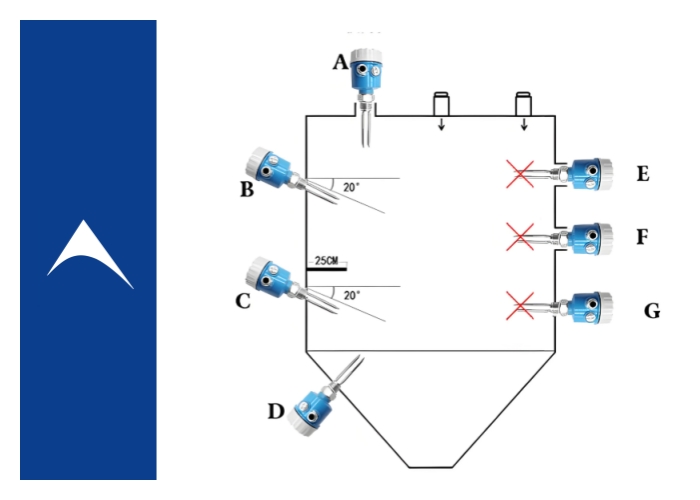

The tuning fork body of the tuning fork level switch is usually made of high-strength 316L stainless steel, which has excellent corrosion resistance, dust resistance, and high-temperature resistance. In harsh environments such as corrosive material storage tanks in the chemical industry and areas around high-temperature furnaces in the metallurgical industry, it can ensure the long-term reliable operation of the device. In addition, the device's structural design fully considers the actual application requirements, making it easy to install in silos and hoppers of different shapes and sizes, adapting to diverse industrial scenarios and being able to withstand the test of long-term industrial production environments.

Easy Maintenance

This device has significant advantages in the maintenance aspect: there is no need for a complex calibration process, and it can be automatically put into operation after installation, effectively shortening the installation and commissioning cycle and reducing labor costs; the intelligent circuit has a built-in self-check function, and users can confirm the operating status of the device through a simple detection program; if the device fails, the problem node can be quickly located, facilitating timely maintenance operations, greatly reducing maintenance costs and improving production efficiency.

Tuning fork level switchTuning fork level switch