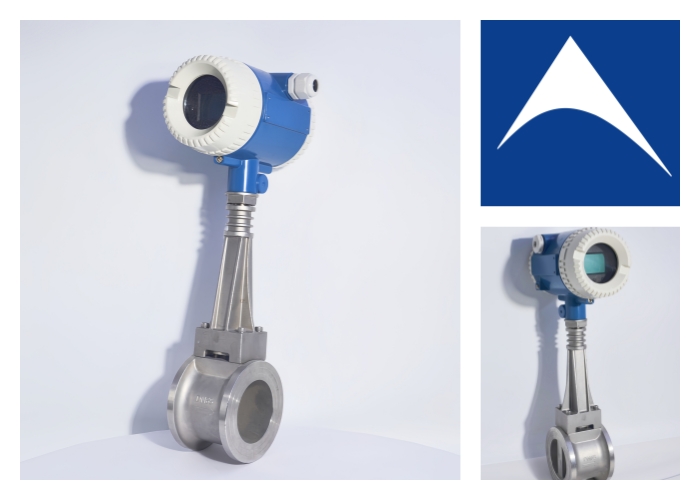

Difference Between AUTO Wafer Type Vortex Flowmeter and Flange Pipe Type Vortex Flowmeter

2025-04-24 14:25

The wafer type and flange pipe type (usually called flange connection type) of vortex flowmeter mainly differ in installation method, pressure resistance, cost and applicable occasions.

Installation method:

Wafer type vortex flowmeter: This type of flowmeter does not have a flange structure itself, but is installed using two existing flanges on the pipeline. The specific operation is to first place the flowmeter between the two flanges, and then fix the flowmeter tightly to the pipeline with bolts and nuts. This method is relatively simple and does not require too many changes to the pipeline.

Flange pipe type flowmeter: This type of flowmeter body has a flange structure and can be directly connected to the flange end on the pipeline by bolts. During the installation process, the flange surfaces at both ends of the instrument need to be aligned with the pipeline flange and tightened with bolts to ensure reliable sealing. This installation method has a stable structure and is suitable for occasions where working conditions are relatively fixed and change less.

Pressure resistance and caliber range:

Wafer type vortex flowmeter: Due to its structural characteristics, it usually has low pressure resistance and a small caliber range. This is because the clamping type's fixing method limits its ability to withstand higher pressures and is not suitable for large-diameter pipes.

Flange pipe type flowmeter: has higher pressure resistance and a wider range of diameters. Since the flange is directly integrated on the flow meter and docked with the pipe flange, it can withstand higher working pressures and is suitable for high-pressure and large-diameter industrial applications.

Cost:

Wafer type vortex flowmeter: Usually the cost is lower because it does not require its own flange and is easy to install, which can save materials and installation time.

Flange pipe type flowmeter: The cost is relatively high because it includes additional flange parts, and the manufacturing and installation process may be more complicated.

Applicable occasions:

Wafer type vortex flowmeter: Suitable for cost-sensitive occasions, low pressure requirements, and frequent maintenance and replacement.

Flange pipe type flowmeter: Suitable for industrial environments with high pressure, large flow, high requirements for sealing and stability, and those fixed installation locations that do not often need to be disassembled.

In summary, the choice of which type depends mainly on the specific needs in the actual application, including pressure level, pipe size, budget, and whether frequent maintenance is required. Welcome to consult me about AUTO vortex flowmeter, we will reply you as soon as possible!