Considerations for Selecting a Double-Flange Level Transmitter for Special Operating Conditions (Part 2)

2025-08-04 13:55

Considerations for Selecting a Double-Flange Level transmitters or Special Operating Conditions, Such as Negative Pressure, Corrosion, Crystallization, and Viscosity (Part 2)

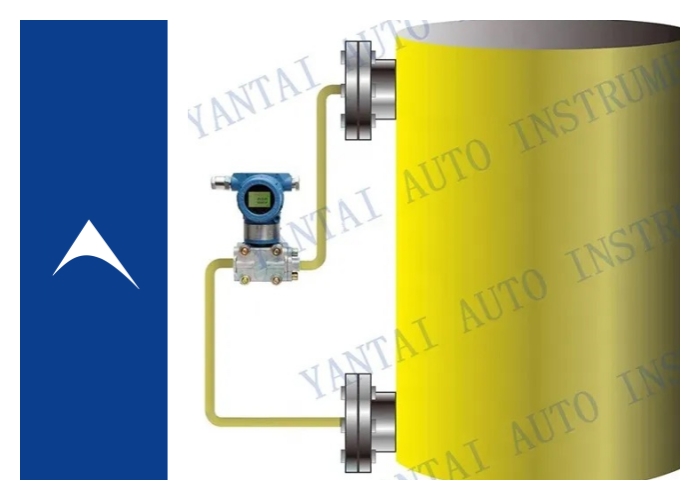

In the previous article, we discussed the key points for selecting double flange differential pressure transmitters under negative pressure and corrosive working conditions. This article will further analyze the selection considerations for special working conditions such as strong crystallinity and viscous media.

1. Viscous Operating Conditions

Problem: Highly viscous media (such as asphalt, heavy oil, and polymer solutions) may adhere to the diaphragm surface, causing sluggish diaphragm response or measurement deviation.

Selection Guide for Double-Flange Level Transmitters:

Diaphragm Material: Choose a smooth, low-adhesion material, such as 316L stainless steel (which has low adhesion to most viscous media) or a PTFE-coated diaphragm (PTFE coating can significantly reduce adhesion to viscous media, but note that PTFE has a maximum temperature resistance of approximately 260°C).

Diaphragm Structure: Prefer convex diaphragms (the raised surface design allows viscous media to slide off more easily due to gravity, reducing adhesion); avoid flat diaphragms (which are prone to accumulation of viscous media).

Installation: If necessary, install a heating device (such as electric heating or a steam jacket) to reduce the viscosity of the media.

2. Corrosive Operating Conditions

Problem: Highly corrosive media (such as acids, alkalis, and organic solvents) may corrode the diaphragm, capillary tube, or transmitter housing, causing leakage or failure.

Selection Guide for Double-Flange Level Transmitters:

Diaphragm Material: Select the appropriate alloy based on the corrosiveness of the media (selection sample):

316L stainless steel: Suitable for mildly corrosive media (such as dilute sulfuric acid and low-concentration hydrochloric acid). Hastelloy C276: Suitable for strongly corrosive media (such as concentrated sulfuric acid, hydrochloric acid, hydrofluoric acid, and chloride solutions).

Monel: Suitable for alkaline media containing chloride ions (such as sodium hydroxide solution).

Capillary Filling Fluid: Choose a corrosion-resistant filling fluid, such as fluorinated oil (resistant to acids, alkalis, and organic solvents). Avoid ordinary silicone oil (which is easily decomposed by acids and alkalis).

Transmitter Housing: Choose a corrosion-resistant housing (such as 316L stainless steel or a protective coating) and ensure sealing (IP66/IP67 protection rating to prevent the intrusion of corrosive gases).

Comprehensive Selection Recommendations

Clarify the characteristics of the media: including corrosiveness (pH value, composition), temperature range, viscosity, and whether it crystallizes or aggregates. Key components to consider: Diaphragm material: Corrosion/temperature/pressure resistance; Capillary fill fluid: Corrosion/low vapor pressure/low viscosity; Transmitter structure: Adaptable to negative pressure/viscosity/crystallization requirements.

Consider maintenance convenience: For example, whether online cleaning, purge ports, or a removable diaphragm are required.

Example combinations: (Example only; specific selection depends on actual operating conditions)

For high-corrosion + negative pressure applications: Hastelloy C276 diaphragm + fluorinated oil fill fluid + reinforced diaphragm cartridge + IP67-rated transmitter.

For viscous + crystallization applications: PTFE-coated flat diaphragm + fluorinated oil fill fluid + removable flange design + heating device.