Considerations for Selecting a Double-Flange Level Transmitter for Special Operating Conditions (Part 1)

2025-07-31 15:14

Considerations for Selecting a Double-Flange Level transmitters or Special Operating Conditions, Such as Negative Pressure, Corrosion, Crystallization, and Viscosity (Part 1)

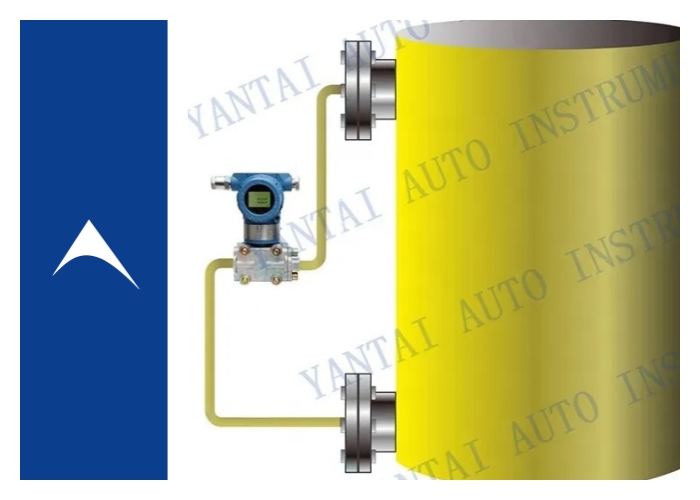

Double-flange level transmitters (differential pressure level transmitters) calculate liquid level by measuring the differential pressure between the diaphragms at the two ends of a container. Key components (such as diaphragm material, capillary fill fluid, diaphragm structure, and whether special treatment is required) must be carefully selected based on the specific operating conditions (e.g., negative pressure, crystallization, viscosity, corrosion, etc.). The following are key selection points and recommendations for different operating conditions:

1. Negative Pressure Conditions

Problem: In high negative pressure environments, the pressure within the container falls below atmospheric pressure, which can cause the capillary fill fluid to vaporize (especially under high temperature conditions), diaphragm deformation, or seal failure, affecting measurement accuracy and even damaging the instrument.

Selection Guide for Double-Flange Level Transmitters:

Diaphragm Material: Prefer materials with strong negative pressure and deformation resistance, such as 316L stainless steel (suitable for conventional negative pressure) or tantalum (suitable for combined corrosion and negative pressure conditions). Capillary Filling Fluid: Avoid easily vaporized silicone oil (such as common DC200 silicone oil) and instead use a low-vapor-pressure filling fluid (such as fluorinated oil, suitable for negative pressure environments between -50°C and 200°C).

Structural Design: Choose a reinforced or more rigid diaphragm, such as a tantalum diaphragm, to reduce the risk of diaphragm deformation.

Verify the Negative Pressure Range: Confirm that the transmitter's range covers negative pressures (e.g., -0.1 to 1.6 MPa) to avoid over-range damage. Alternative (for deep vacuum environments): Use a radar/ultrasonic level gauge: This is completely contactless and unaffected by pressure. Selection Recommendations: If a double-flange level gauge is necessary for high-negative-pressure applications, clarify the following parameters with the manufacturer:

Minimum absolute pressure;

Media temperature (affects fill fluid selection);

Process connection material (high sealing performance is required for deep vacuum applications);

Whether explosion-proof certification is required (for the chemical/pharmaceutical industries). Double-flange level transmitters can be used under low to medium negative pressure conditions through optimized design, but the risks are significant in deep vacuum environments, so it is recommended to prioritize non-pressure-dependent level instruments.

2. Crystallization Conditions

Problem: Crystallization of the medium on the flange diaphragm surface (such as salt or sugar solutions) can clog the diaphragm gap or cover the diaphragm, leading to corrosion and measurement failure.

Selection Guide for Double-Flange Level Transmitters:

Choose a material that is resistant to crystallization corrosion and easy to clean, such as 316L stainless steel (corrosion-resistant to most crystallizing media) or Hastelloy C276 (for combined conditions of severe corrosion and crystallization). If the crystallization temperature is high, consider Monel alloy (resistant to high-temperature chloride crystallization).

Diaphragm and Flange Structure Optimization

Prefer a flush diaphragm to avoid crystal accumulation (prevent crystals from accumulating in the groove);

Diaphragm Surface Treatment: Polish or apply a Teflon coating (high-temperature and corrosion-resistant, and less prone to buildup) to reduce crystal adhesion.

For high-viscosity crystallization, use an inserted diaphragm design to allow the diaphragm to penetrate deeper into the equipment, avoiding the crystallization zone. Auxiliary measures: Install a purge device (such as nitrogen purge) at the flange to regularly remove crystals from the diaphragm surface; or choose a flange design with a flushing port to facilitate online cleaning.

Selection Recommendations (Core Requirements):

Flush diaphragm with no dead angles + PTFE coating (Teflon);

Upgrade the material to Hastelloy/Tantalum based on the corrosion resistance of crystallization;

Implement forced heating to maintain the temperature above the crystallization point;

Install a flushing ring and a dual valve block (for easy inspection and maintenance);

Go deep into the vessel to avoid the crystallization zone.

Change the conventional installation method.

Be sure to provide the manufacturer with the specific crystal composition, concentration, and temperature curve for customized verification!