Summary of key points of orifice flowmeter installation and fault analysis

2025-07-23 14:56

When measuring flow with an orifice plate flowmeter, why is it reasonable to install the orifice plate in front of the regulating valve?

① When measuring flow with a throttling device, there are two requirements in theory, namely, the fluid flow is continuous and the law of conservation of energy is followed during the fluid flow process. This tells us that the orifice plate flowmeter cannot be installed in places where gas and liquid coexist, so as not to increase the measurement error.

② Some liquids (such as liquefied hydrocarbons) are sometimes partially gasified after the pressure is reduced by the regulating valve, forming a two-phase coexistence. Therefore, the orifice plate flowmeter should be installed in front of the regulating valve as much as possible, and this installation method is reasonable.

How are explosive gas hazardous places divided? What are the characteristics of intrinsically safe instruments?

For explosive gas hazardous places, there are 3 areas, namely Zone 0, Zone 1 and Zone 2. Their corresponding definitions are as follows:

Zone 0: Under normal circumstances, explosive gas mixtures exist continuously or for a long time.

Zone 1: Under normal circumstances, explosive gas mixtures may appear in places.

Zone 2: Under normal circumstances, explosive gas mixtures are unlikely to appear, or even if they appear, they only exist for a short time.

Features of intrinsically safe instruments

① Intrinsically safe instruments are also called safe spark instruments;

② Its characteristics are that when the instrument is in normal state or fault state, the sparks generated by the circuit and system and the temperature reached will not cause the explosive mixture to explode. Exia intrinsically safe equipment is the only explosion-proof electrical equipment that can be installed in Zone 0.

The process reflects that a newly installed orifice plate flowmeter indicates inaccurately (the secondary meter is DCS), and it is normal for the instrument worker to calibrate the transmitter. Please analyze what other reasons are there?

1. Balance valve leakage

2. Does the orifice plate flowmeter have a second square root

3. The DCS and transmitter range settings are inconsistent

4. The density of the process medium changes

5. The safety device is not calibrated

6. The orifice is installed upside down

7. The pressure pipe leaks or has bubbles

8. The isolation fluid is not filled well, and there is a liquid column difference

9. The process bypass leaks

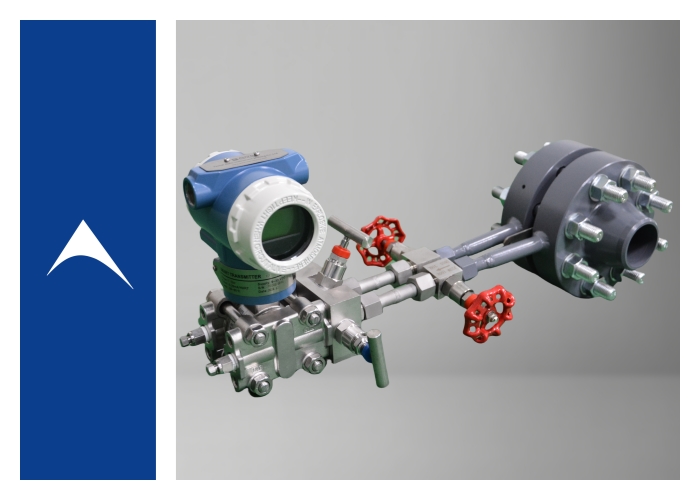

AUTO Instrument also manufactures high-quality orifice flowmeters, helping you build accurate and reliable flow measurement solutions. We are committed to supporting your process control needs with proven performance and expert engineering!