4-20mA Stream Argon Gas Vortex Flow Meter

- Information

- Product Description

- Video

- Download

Product Introduction

At present, the most widely used vortex flow meter in the market is the LUGB series vortex type flow meter. The vortex flow meter is mainly used for flow measurement of industrial pipeline medium fluid. It is characterized by small pressure loss, large measuring range and high accuracy. It is almost independent of fluid density, pressure, temperature, viscosity and other parameters when measuring volume flow under working conditions. The vortex street steam flowmeter adopts piezoelectric stress sensor, which has high reliability and is easy to be used with computer and other digital systems. It is an advanced and ideal measuring instrument.

Product Features

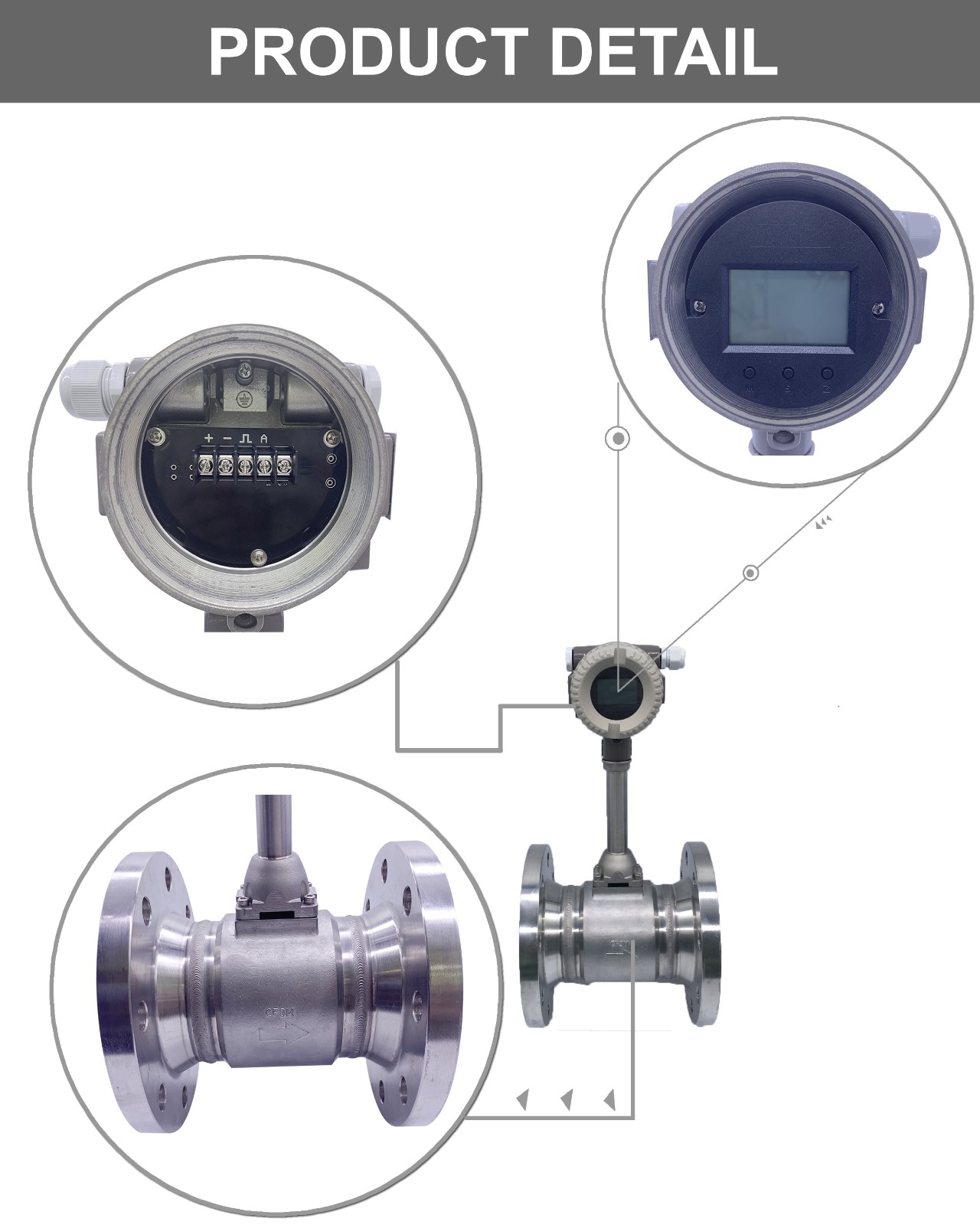

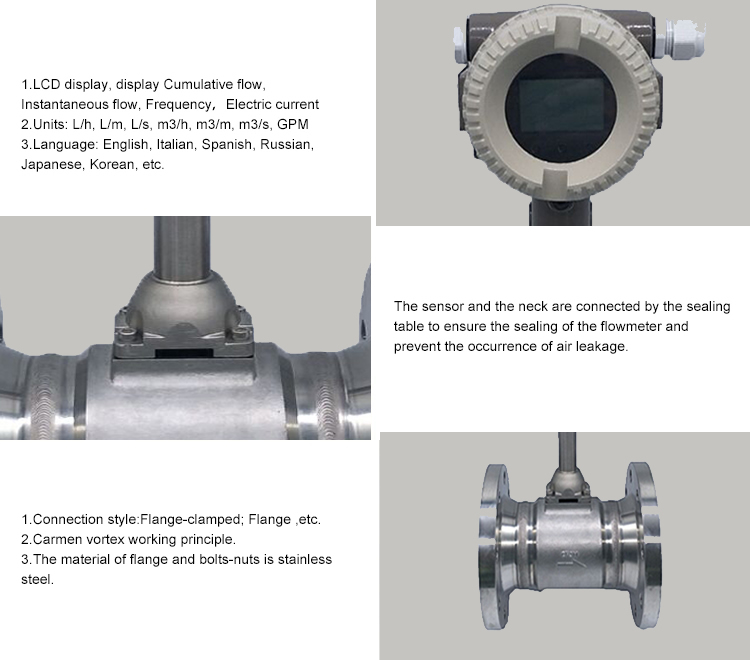

On site LCD display, pulse, 4-20ma output or RS485 communication, can be connected with industrial automation system

with various structural forms, and can be made into full pipe type or plug-in type to measure large pipe diameter flow.

Wide temperature range up to highest temperature 350℃

Adopt Japan OVAL technology and design

No moving parts, no abrasion, non-wearing parts inside, fully welded SS304 body (Optional SS316)

Product Parameters

Nominal diameter (mm) | 25,40,50,65,80,100,125,150,200,250,300,(300~1000 Insert type) |

Nominal pressure (MPa) | DN25-DN200 4.0(>4.0 Supply agreement),DN250-DN300 1.6(>1.6 Supply agreement) |

Medium temperature(°C) |

Piezoelectric type:-40~260,-40~320;Capacitance type : -40~300, -40~400,-40~450(Supply agreement)

|

Body material

| 1Cr18Ni9Ti,(Other materials supply agreement) |

Allowable vibration acceleration

| Piezoelectric type:0.2g Capacitance type:1.0~2.0g |

Accuracy

| ±1%R,±1.5%R,±1FS;Insert type:±2.5%R,±2.5%FS |

Range of

| 1:6~1:30 |

Power supply voltage |

Sensor:+12V DC,+24V DC;Transmitter:+12V DC ,+24V DC;Battery type:3.6V Battery

|

Output signal

| Square wave pulse ( not including the battery power supply type ): high level or low level5V,1V; current: 4~ 20mA |

Pressure loss coefficient

| In line with the JB / T9249standard Cd = 2.4 |

Explosion proof marks

| Intrinsic safety type: Exd IA CT2-T5 flameproof type: Exd CT2-T5 |

Protection grade

| The ordinary IP65 diving type IP68 |

Environmental conditions

| Temperature - 20~ 55,5% ~ 90% of relative humidity, atmospheric pressure is 86 ~ 106kPa |

Applicable medium

| Gas, liquid, steam |

Transmission distance

| Three wire system pulse output type: < 300m, two line standard current output type (4 ~ 20mA ): load resistance less than 750ohm |

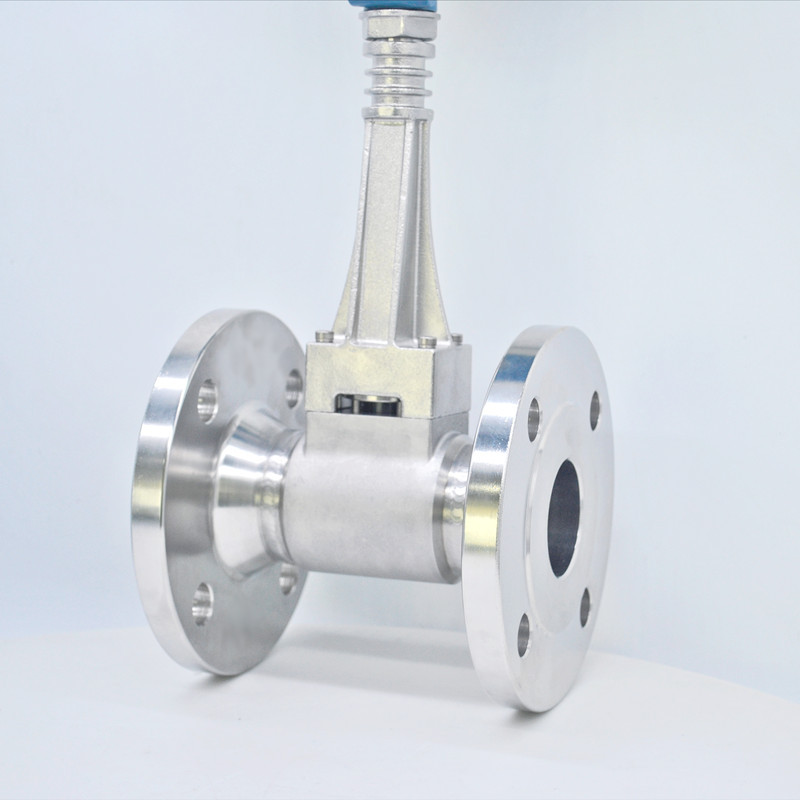

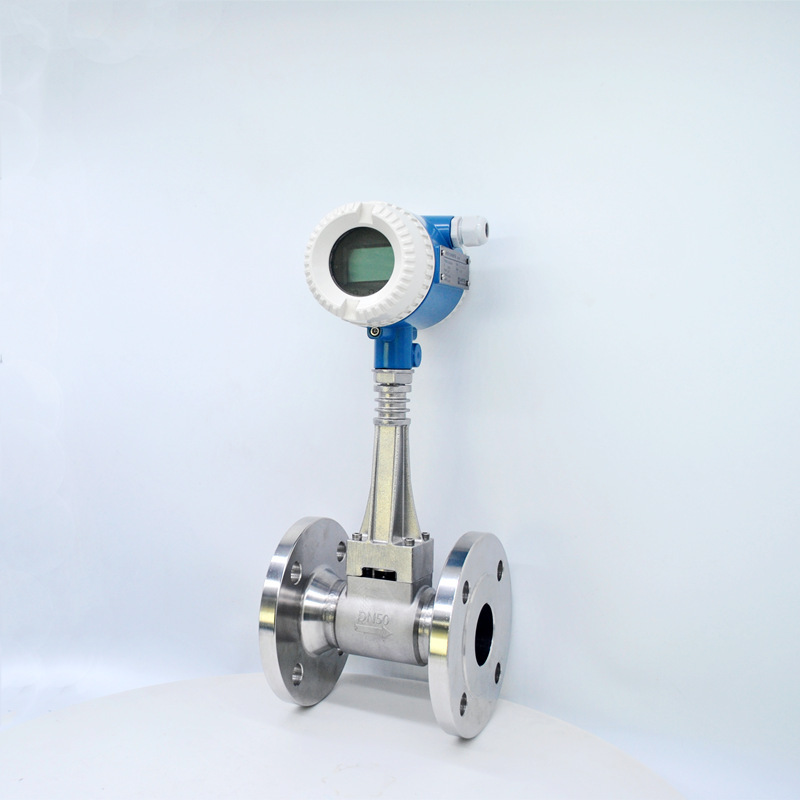

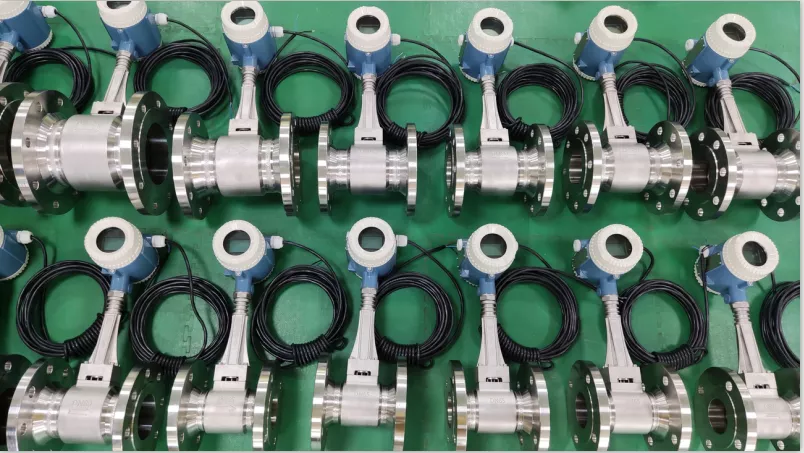

Product detailed images

Product order sheet

LUGB | Explanation | ||

Nominal diameter (In mm) | diameter | DN15-300(Pipeline) | |

DN200-1500(Plug-in) | |||

Connection | Pipeline | FL | Flange connection |

JZ | Flange clamp | ||

Z | Special rules | ||

Insert | J | Simple Formula | |

Q | Ball type | ||

Accuracy | Pipe line | 10 | 1.0%R |

15 | 1.5%R | ||

Insert | 20 | 2.0%R | |

25 | 2.5%R | ||

Z | Special accuracy standards | ||

Temperature and pressure | S | T(S)P(S)At normal temperature and pressure | |

Z | T(Z)P(Z)Twin extreme pressure | ||

Communication protocol | N | No communication interface | |

H | HART protocol | ||

M | MODBUS protocol | ||

Output | 1 | No output | |

2 | Two-wire 4-20mA output | ||

3 | Pulse output | ||

D | DC12V | ||

Power supply | DB | Dual 12V power supply and battery | |

DD | DC24V | ||

B | Battery 3.6V power supply, no signal output uses only | ||

Sensor Material | S | 304Stainless steel | |

L | 316Stainless stee | ||

Core Component Materials | S | 304Stainless steel Probes | |

L | 316Stainless steel Probes | ||

Measuring medium | 1 | Gas | |

2 | Liquid | ||

3 | Saturated steam | ||

4 | Superheated steam | ||

Production line

2. The vortex type flow meter has simple and direct indication.The flow sensor has power indication and flow status indication. The flow status in the current pipeline can be displayed visually.

3. The Vortex type flow meter is applicable to various fluid media.The flow switch of the same model in the flow sensor can be used for gas, such as natural gas and argon gas, and also for liquid, such as water, oil, etc. The flow of gas and liquid can be monitored by adjusting the knob in the flow switch.