The on-site liquid level and the remote liquid level don't match?

2025-10-22 14:57

Everyone must have encountered the problem that the on-site magnetic flap level gauge and the remote liquid level gauge show different levels. It's not very difficult, but it's not very simple either. Let's analyze the causes of the fault and how to deal with it this time.

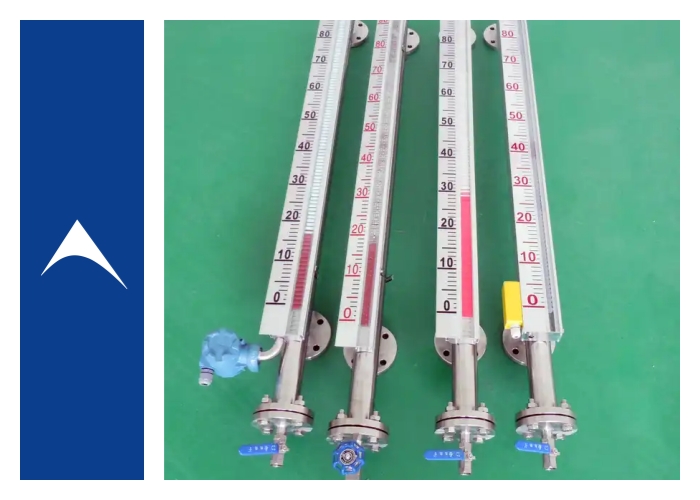

The advantage of the magnetic flap level gauge is that it is intuitive and can clearly display the liquid level in the tank, which is convenient for on-site operators to observe. While the remote liquid level gauge is convenient for operators in the control room to monitor, sometimes it may show a deviation due to signal transmission issues. Therefore, installing both on-site and remote liquid level gauges can provide more comprehensive and reliable liquid level monitoring, improving production efficiency and safety.

This is the logic. What factors cause the two liquid levels to be inconsistent? The first one is human factors. I think it's not necessary to describe it too specifically. This is a very abstract factor, so abstract that it can't even be described by Picasso's paintings. It's a very mysterious and uncertain factor.

If we have to express it in words, for example, there is a sealed tank containing 32% alkali solution. The magnetic flap shows 1.2 meters, while the remote liquid level gauge shows 1.26 meters.

The on-site operator reports to the control room like this: The on-site magnetic flap only shows a liquid level of one meter. Let the instrument technician come and check it as it doesn't match the control room.

Seeing such a big difference, of course, they rush to the site to check. They look at the magnetic flap and then the remote gauge; the liquid levels don't seem to be that different? Is it the control room that doesn't match?

When they ask the control room, the reading is consistent with the transmitter, and the current has also been measured and there's no problem! ? Could it be that the magnetic flap level gauge is broken? I tried to attract the float with a magnet. It moved. When I let go, the magnetic flap level gauge still showed 1.2 meters. Until the team leader came over, he also thought there was nothing wrong. He then asked the field operator what had happened at that time. The field operator said that the liquid level was 1 meter at that time, but now it's 1.2 meters. He didn't know why the liquid level had risen by 20 centimeters. Was it 1 meter before? Right? The team leader asked. The field operator replied: Yes, it was 1 meter. The team leader then asked: Did you just open the inlet valve of the tank? The field operator answered: Yes. So, human factors are a very abstract concept. It's probably because modern medical technology has advanced, allowing some people who were destined to be eliminated in nature to survive in modern society.

The second factor is that the design requirements of the remote level gauge do not meet the production needs. This is also an abstract concept. Unless the parameters were not set properly when replacing the level gauge, the selected level gauge range does not meet the requirements, or the installation is not standardized, etc., it is mostly due to human factors.

The third factor is the change in medium density. As is well known, sealed or open containers mostly use double-flange and single-flange level gauges. These two types of level gauges that work based on the principle of differential pressure will cause a certain deviation between the magnetic flap and the remote level gauge when the internal medium density changes. This deviation is actually relatively small, unless someone mistakenly fills other media into it.

The last one is that the magnetic flap is stuck at a certain position and does not change for a long time. Only the remote level gauge changes. In this case, it's very simple. Just disassemble the internal part to check if the float is stuck, if the float is damaged and the liquid inside increases the density, or if the float loses its magnetism. In short, just check the float. Considering all the above reasons, is there a simple and efficient method to troubleshoot? Yes, there is. First, get a metrology certificate and obtain the qualification of a third-party metrology. Then, buy a dipstick. Use the dipstick to measure the liquid level in the tank and get a third-party liquid level that everyone can trust. Once you have the accurate liquid level, you can then check the magnetic flap level gauge and the transmitter.

If the tank is still receiving materials, it's best to stop the feeding first. You can also continue, but you'll need to measure the liquid level in the tank more frequently. As for the interval for going up to the top of the tank to measure, you decide. One person definitely can't handle it.

Note: All the above are for open containers.

What about sealed containers? This requires a thorough understanding of the parameters, medium density, and working principle of the sealed tank. It mainly depends on whether the relevant data can be found.

But! These are too complicated, so I asked a good friend to summarize a basic three-step inspection method that is generally applicable:

① First, check the magnetic flap level gauge. Use a strong magnet to attract the float and drag it to prove that the on-site level gauge is normal. (If it's a glass tube level gauge, just rest assured. As long as it's not damaged, it's fine.)

② Use the on-site level as a reference and use field communication devices such as 475 to check the parameters.

③ Calculate. Based on the current medium density, calculate the pressure difference in the liquid level displayed by the magnetic flap level gauge. Compare it with the pressure difference measured by the transmitter (it's fine if it's approximately the same). If the difference is large, check the sensor. It's either blocked or leaking. You'll find it for sure.

The core of the above content is actually to need an accurate liquid level as a factual basis. Based on this liquid level, check and adjust. Combining the use of two types of level gauges is also very convenient when troubleshooting. Gradually accumulate experience, and I believe that when you encounter such things that are neither too difficult nor too easy in the future, you won't be intimidated.

magnetic flap level gaugemagnetic flap level gauge