Static Pressure Level Gauge Selection Guide: Facing Complex Working Conditions, Are You Making the Right Choice?

2025-09-28 15:05

Static pressure level gauges are based on the principle of fluid statics: the static pressure at a point in a liquid is proportional to the height from that point to the liquid surface (P = ρgh, where ρ is the liquid density, g is the acceleration due to gravity, and h is the height). By measuring the static pressure at the tank bottom or at a specific point, the liquid level can be calculated.

Analyzing Media Characteristics

1. Corrosiveness: For corrosive media such as acids and alkalis, the contact parts must be made of corrosion-resistant materials. For example:

2. Mildly corrosive media (clean water, sewage): Choose a 316L stainless steel probe.

3. Strong acids and alkalis: Choose a probe or flange lining made of materials such as polytetrafluoroethylene (PTFE) or polypropylene (PPR).

4. Foods and pharmaceuticals: Choose food-grade materials that meet hygiene standards, such as silicone rubber seals.

5. Viscosity and Impurities: For oils, slurries, and media that easily crystallize, flange-type gauges are a better choice, as their measuring diaphragms are less susceptible to clogging or adhesion. If using a submersible level gauge, impurities in the medium may clog the air guide holes.

6. Temperature: The medium's temperature range directly influences the sensor type you choose. For example, some submersible level gauges have a medium temperature range of -20°C to 85°C. However, high-temperature media (e.g., exceeding 125°C) may not be suitable for certain submersible level gauges, requiring a special model or flange-type sensor.

Select based on operating conditions ("Where to measure")

Vessel Type (Open vs. Sealed):

Open vessel (normal pressure): Submersible level gauges are the most economical and common choice, as they can directly compensate for atmospheric pressure.

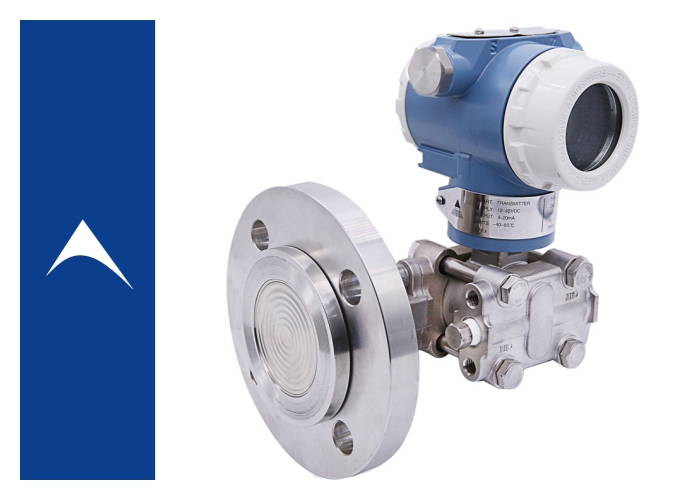

Sealed vessel (pressurized): A flange-type level gauge is essential, as it measures process pressure and must withstand the tank's internal pressure, which is factored into its zero calibration.

Temperature and Pressure Range:

Temperature: Determine the temperature range of the medium and environment. Standard models typically support -20°C to 80°C. High-temperature media (e.g., exceeding 125°C) require a high-temperature model (with a high-temperature-resistant filler fluid and heat dissipation structure).

Pressure: For sealed vessels, the operating pressure must be lower than the rated pressure of the level gauge. Flange-type level gauges can generally withstand higher pressures.

Safety and Protection Requirements:

Explosion-proof Requirements: In locations where flammable and explosive gases are present, such as in the petroleum, chemical, and gas industries, a model with explosion-proof certification, such as Exd IIC T6 Gb (flameproof) or Exia IIC T6 Ga (intrinsically safe), must be selected.

Ingress Protection (IP Code): For sensors permanently immersed in liquid, the sensor must meet a minimum IP68 rating. The junction box or meter head should meet IP65 or higher for dust and water protection.

Installation Method: A Critical Factor Often Underestimated

Submersible installation is simple and straightforward, making it suitable for open vessels operating under normal pressure conditions. However, attention must be paid to the tensile strength of the cable, especially in deep well applications, where the combined weight of the level gauge and the cable may exceed the maximum tolerance. Some manufacturers provide armored cable options, which significantly enhance tensile strength and long-term pressure resistance.

Flange installation is more common on pressure vessels, as it allows the level gauge to withstand both liquid pressure and internal tank pressure. One important detail that is often overlooked is the difference in flange standards. The sizes and pressure ratings of national, American, and Japanese standard flanges vary, so these specifications must be clearly defined when ordering. In some projects, flanges have already been welded, only to discover later that they do not match the level gauge flange pressure requirements. Such mistakes can directly compromise measurement accuracy and pressure safety.

Threaded installation may appear simple, but thread standards also differ significantly. G-threads, NPT threads, and BSP threads cannot be mixed, and sealing methods vary between face seals and threaded seals. Selecting the wrong standard can cause leaks, pressure instability, or even complete installation failure. These details, though small, often determine the overall success or failure of a project involving pressure measurement.