Principle, Classification, and Applications of Temperature Transmitters (Part I)

2025-06-12 10:49

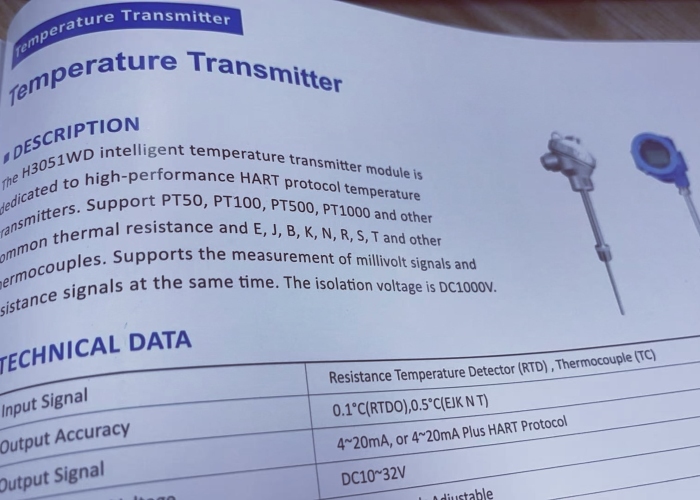

In modern industry, the temperature transmitter is more than just a common component—it's a key part of many critical systems. From automated manufacturing to medical diagnostics and environmental monitoring, products are widely used to track and manage temperature with accuracy and efficiency. This article will introduce their basic working principles, main types, and how they are applied in real-world scenarios.

How a Temperature Transmitter Works

At its core, a temperature transmitter senses changes in temperature and converts them into electrical signals that can be read and analyzed. The underlying principles can vary depending on the type, including thermoelectric effects, resistance changes, thermistors, and infrared absorption.

Among these, thermistor-based temperature transmitters are particularly common. Thermistors change their resistance depending on temperature. There are two main types:

PTC (Positive Temperature Coefficient): Resistance increases with temperature.

NTC (Negative Temperature Coefficient): Resistance decreases as temperature rises.

Different materials are used for different purposes. For example:

PT100 (platinum-based)

CU50 (copper-based)

NI100 (nickel-based)

All of them serve as the core sensing elements in various temperature transmitters.

Main Types of Temperature Transmitters

1. Contact Type

These require direct contact with the surface or material being measured. The reading is based on the heat transfer between the object and the sensor. Common examples include thermocouples, RTDs, and semiconductor-based transmitters.

2. Non-contact Type

This kind of temperature transmitter measures radiation, typically infrared or laser, emitted by an object. They're ideal when direct contact isn't possible—such as in moving or high-temperature objects. Infrared and laser products fall under this category.

3. Portable Temperature Meters

Often digital and battery-powered, portable meters are small, fast, and easy to carry—used frequently for quick checks in the field, whether for air, liquid, or gas temperature.

Where Temperature Transmitters Are Used

1. Industrial Automation

Temperature transmitters are crucial for controlling temperatures in equipment like furnaces, boilers, and cooling systems. They help maintain safety and process consistency.

2. Environmental Monitoring

They are used to monitor ambient conditions—whether tracking indoor air temperature, greenhouse climate, or even underground water temperatures.

3. Healthcare and Medical Use

In medical settings, products help monitor patient body temperature, blood temperature, and the temperature of IV fluids, contributing to safe and effective care.

4. Military and Defense

Defense applications often require precise monitoring—for instance, tracking the barrel temperature of artillery or managing engine temperatures in aircraft.

This concludes Part I of our overview of temperature transmitters. In the next installment, we'll look at how to choose the right products, how to install it correctly, and how it compares to thermocouples.